Precision Aerospace Engineering

Custom-crafted drone fuselages with military-grade precision

Scroll Down

Custom-crafted drone fuselages with military-grade precision

Scroll Down

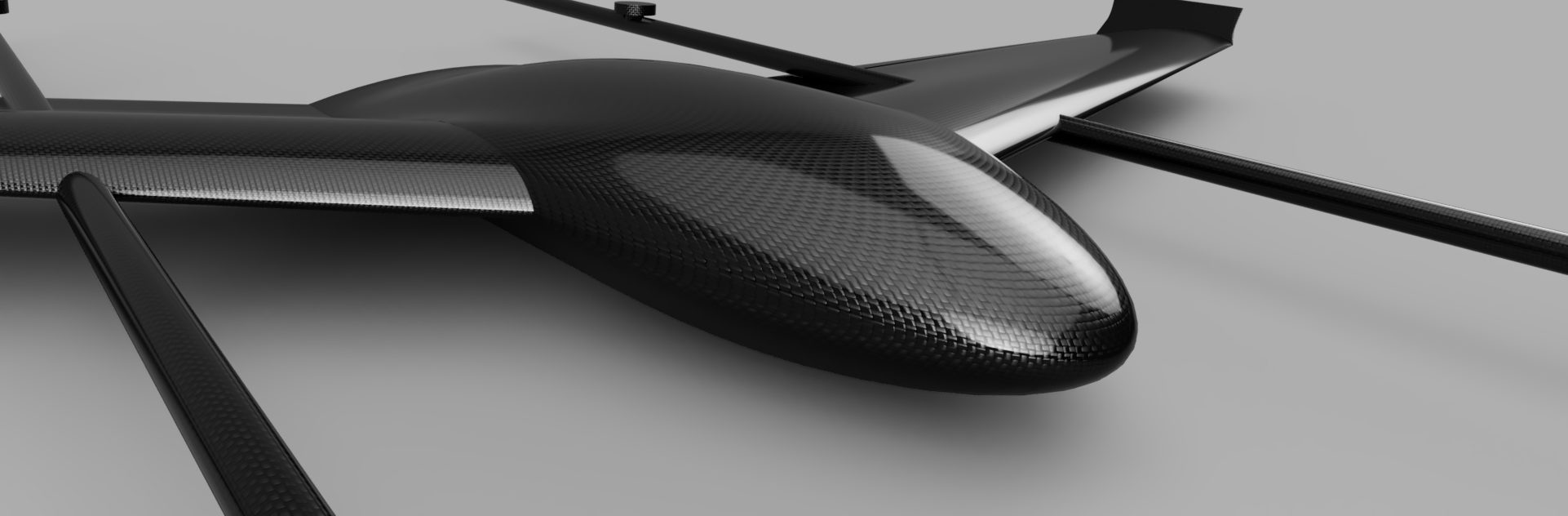

Leading the future of aerospace manufacturing

At V-UAV TECH, we handcraft every component of our drone fuselages with precision engineering and innovative design. Our advanced manufacturing processes ensure that each product meets the highest standards of quality and performance.

Founded by aerospace engineers with decades of combined experience, we specialize in creating custom solutions for commercial, research, and military applications worldwide.

Precision engineering from concept to flight

Our team of engineers creates detailed 3D models with aerodynamic simulations to ensure optimal performance.

Using advanced CNC machining and composite layering techniques for aerospace-grade components.

Rigorous testing with tolerances measured to 0.01mm precision using laser scanning technology.

Each design undergoes extensive flight testing to validate performance in real-world conditions.

Discover our premium selection of custom-crafted drone fuselages and components.

View ProductsEngineering precision in every detail

3K twill weave carbon fiber with aerospace-grade epoxy resin matrix

7075-T6 aluminum alloy for structural components

Ti-6Al-4V (Grade 5) titanium for high-stress components

CNC Machined Components

Full Fuselage Assemblies

Inspection Methods

Wind Tunnel Validated

Load Testing Results

Operational Conditions

Get in touch to discuss your custom drone requirements

+1 253 422 5592

Get quick responses to your inquiries through our WhatsApp business account

Chat with Us